UNITED

STATES

SECURITIES

AND EXCHANGE COMMISSION

Washington,

D. C. 20549

FORM

10-K

|

x

|

ANNUAL

REPORT PURSUANT TO SECTION 13 OR 15(d) OF THE SECURITIES EXCHANGE ACT OF

1934

|

For the

fiscal year ended September 30, 2009

Commission

File Number 0-09115

MATTHEWS

INTERNATIONAL CORPORATION

(Exact

name of registrant as specified in its charter)

|

COMMONWEALTH

OF PENNSYLVANIA

|

25-0644320

|

|

(State

or other jurisdiction of

|

(I.R.S.

Employer

|

|

incorporation

or organization)

|

Identification

No.)

|

|

|

|

|

TWO

NORTHSHORE CENTER, PITTSBURGH, PA

|

15212-5851

|

|

(Address

of principal executive offices)

|

(Zip

Code)

|

|

Registrant's

telephone number, including area code

|

(412)

442-8200

|

Securities

registered pursuant to Section 12(b) of the Act:

|

Title

of each class

|

|

Name

of each exchange on which registered

|

|

Class

A Common Stock, $1.00 par value

|

|

NASDAQ

Global Select Market System

|

Securities

registered pursuant to Section 12(g) of the Act: None

Indicate

by check mark if the registrant is a well-known seasoned issuer, as defined in

Rule 405 of the Securities Act.

Yes x No

o

Indicate

by check mark if the registrant is not required to file reports pursuant to

Section 13 or Section 15(d) of the Act.

Yes o No

x

Indicate

by check mark whether the registrant (1) has filed all reports required to be

filed by Section 13 or 15(d) of the Securities Exchange Act of 1934 during the

preceding 12 months (or for such shorter period that the registrant was required

to file such reports), and (2) has been subject to such filing requirements for

the past 90 days. x

Indicate

by check mark if disclosure of delinquent filers pursuant to Item 405a of

Regulation S-K is not contained herein, and will not be contained, to the best

of registrant's knowledge, in definitive proxy or information statements

incorporated by reference in Part III of this Form 10-K or any amendment to this

Form 10-K. o

Indicate

by check mark whether the registrant has submitted electronically and posted on

its corporate Web site, if any, every Interactive Data File required to be

submitted and posted pursuant to Rule 405 of Regulation S-T during the preceding

12 months (or for such shorter period that the registrant was required to submit

and post such files).

Indicate

by check mark whether the registrant is a large accelerated filer, an

accelerated filer, a non-accelerated filer or a smaller reporting company. See

definition of “large accelerated filer”, “accelerated filer”, and “smaller

reporting company” in Rule 12b-2 of the Exchange Act.

|

Large

accelerated filer x

|

Accelerated

filer o

|

Non-accelerated

filer o

|

Smaller

reporting company o

|

Indicate

by check mark whether the registrant is a shell company (as defined in Rule

12b-2 of the Exchange Act). Yes o No x

The

aggregate market value of the Class A Common Stock outstanding and held by

non-affiliates of the registrant, based upon the closing sale price of the Class

A Common Stock on the NASDAQ Global Select Market System on March 31, 2009, the

last business day of the registrant’s most recently completed second fiscal

quarter, was approximately $867 million.

As of

October 31, 2009, shares of common stock outstanding were: Class A Common Stock

30,331,268 shares

Documents incorporated by

reference: Specified portions of the Proxy Statement for the 2010 Annual

Meeting of Shareholders are incorporated by reference into Part III of this

Report.

The

index to exhibits is on pages 74-76

PART

I

CAUTIONARY

STATEMENT REGARDING FORWARD-LOOKING INFORMATION:

Any

forward-looking statements contained in this Annual Report on Form 10-K

(specifically those contained in Item 1, "Business", Item 1A, “Risk Factors” and

Item 7, "Management's Discussion and Analysis of Financial Condition and Results

of Operations") are included in this report pursuant to the "safe harbor"

provisions of the Private Securities Litigation Reform Act of

1995. Such forward-looking statements involve known and unknown risks

and uncertainties that may cause the Company's actual results in future periods

to be materially different from management's expectations. Although

Matthews International Corporation (“Matthews” or the “Company”) believes that

the expectations reflected in such forward-looking statements are reasonable, no

assurance can be given that such expectations will prove

correct. Factors that could cause the Company's results to differ

materially from the results discussed in such forward-looking statements

principally include changes in domestic or international economic conditions,

changes in foreign currency exchange rates, changes in the cost of materials

used in the manufacture of the Company’s products, changes in death rates,

changes in product demand or pricing as a result of consolidation in the

industries in which the Company operates, changes in product demand or pricing

as a result of domestic or international competitive pressures, unknown risks in

connection with the Company's acquisitions and technological factors beyond the

Company's control. In addition, although the Company does not have

any customers that would be considered individually significant to consolidated

sales, changes in the distribution of the Company’s products or the potential

loss of one or more of the Company’s larger customers are also considered risk

factors.

Matthews,

founded in 1850 and incorporated in Pennsylvania in 1902, is a designer,

manufacturer and marketer principally of memorialization products and brand

solutions. Memorialization products consist primarily of bronze

memorials and other memorialization products, caskets and cremation equipment

for the cemetery and funeral home industries. Brand solutions include

graphics imaging products and services, marking products, and merchandising

solutions. The Company's products and operations are comprised of six business

segments: Bronze, Casket, Cremation, Graphics Imaging, Marking

Products and Merchandising Solutions. The Bronze segment is a leading

manufacturer of cast bronze memorials and other memorialization products, cast

and etched architectural products and is a leading builder of mausoleums in the

United States. The Casket segment is a leading casket manufacturer

and distributor in North America and produces a wide variety of wood and metal

caskets. The Cremation segment is a leading designer and manufacturer

of cremation equipment and cremation caskets primarily in North America. The

Graphics Imaging segment manufactures and provides brand solutions, printing

plates, gravure cylinders, pre-press services and imaging services for the

primary packaging and corrugated industries. The Marking Products

segment designs, manufactures and distributes a wide range of marking and coding

equipment and consumables, and industrial automation products for identifying,

tracking and conveying various consumer and industrial products, components and

packaging containers. The Merchandising Solutions segment designs and

manufactures merchandising displays and systems and provides creative

merchandising and marketing solutions services.

At

October 31, 2009, the Company and its majority-owned subsidiaries had

approximately 4,500 employees. The Company's principal executive

offices are located at Two NorthShore Center, Pittsburgh, Pennsylvania 15212,

its telephone number is

(412)

442-8200 and its internet website is www.matw.com. The

Company files all required reports with the Securities and Exchange Commission

(“SEC”) in accordance with the Exchange Act. These reports are

available free of charge on the Company’s website as soon as practicable after

being filed or furnished to the SEC. The reports filed with the SEC are also

available to read and copy at the SEC’s Public Reference Room at 100 F Street,

N.E., Washington, D.C. 20549 or by contacting the SEC at

1-800-732-0330. All reports filed with the SEC can be found on its

website at www.sec.gov.

The

following table sets forth reported sales and operating profit for the Company's

business segments for the past three fiscal years. Detailed financial

information relating to business segments and to domestic and international

operations is presented in Note 16 (“Segment Information”) to the Consolidated

Financial Statements included in Part II of this Annual Report on Form

10-K.

|

ITEM

1.

|

BUSINESS,

continued

|

|

|

|

Years

Ended September 30,

|

|

|

|

|

2009

|

|

|

2008

|

|

|

2007

|

|

|

|

|

Amount

|

|

|

Percent

|

|

|

Amount

|

|

|

Percent

|

|

|

Amount

|

|

|

Percent

|

|

|

|

|

(Dollars

in Thousands)

|

|

|

Sales

to unaffiliated customers:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Memorialization:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bronze

|

|

$ |

215,934 |

|

|

|

27.7 |

% |

|

$ |

243,063 |

|

|

|

29.7 |

% |

|

$ |

229,850 |

|

|

|

30.7 |

% |

|

Casket

|

|

|

203,247 |

|

|

|

26.0 |

|

|

|

219,792 |

|

|

|

26.8 |

|

|

|

210,673 |

|

|

|

28.1 |

|

|

Cremation

|

|

|

30,909 |

|

|

|

4.0 |

|

|

|

26,665 |

|

|

|

3.3 |

|

|

|

25,166 |

|

|

|

3.3 |

|

|

|

|

|

450,090 |

|

|

|

57.7 |

|

|

|

489,520 |

|

|

|

59.8 |

|

|

|

465,689 |

|

|

|

62.1 |

|

|

Brand

Solutions:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Graphics

Imaging

|

|

|

234,966 |

|

|

|

30.1 |

|

|

|

203,703 |

|

|

|

24.9 |

|

|

|

146,049 |

|

|

|

19.5 |

|

|

Marking

Products

|

|

|

42,355 |

|

|

|

5.4 |

|

|

|

60,031 |

|

|

|

7.3 |

|

|

|

57,450 |

|

|

|

7.7 |

|

|

Merchandising

Solutions

|

|

|

53,497 |

|

|

|

6.8 |

|

|

|

65,369 |

|

|

|

8.0 |

|

|

|

80,164 |

|

|

|

10.7 |

|

|

|

|

|

330,818 |

|

|

|

42.3 |

|

|

|

329,103 |

|

|

|

40.2 |

|

|

|

283,663 |

|

|

|

37.9 |

|

|

Total

|

|

$ |

780,908 |

|

|

|

100.0 |

% |

|

$ |

818,623 |

|

|

|

100.0 |

% |

|

$ |

749,352 |

|

|

|

100.0 |

% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Operating

profit:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Memorialization:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Bronze

|

|

$ |

57,598 |

|

|

|

57.0 |

% |

|

$ |

71,576 |

|

|

|

53.8 |

% |

|

$ |

66,298 |

|

|

|

59.3 |

% |

|

Casket

|

|

|

17,716 |

|

|

|

17.5 |

|

|

|

23,339 |

|

|

|

17.6 |

|

|

|

11,801 |

|

|

|

10.6 |

|

|

Cremation

|

|

|

5,036 |

|

|

|

5.0 |

|

|

|

5,474 |

|

|

|

4.1 |

|

|

|

3,631 |

|

|

|

3.2 |

|

|

|

|

|

80,350 |

|

|

|

79.5 |

|

|

|

100,389 |

|

|

|

75.5 |

|

|

|

81,730 |

|

|

|

73.1 |

|

|

Brand

Solutions:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Graphics

Imaging

|

|

|

19,217 |

|

|

|

19.0 |

|

|

|

18,617 |

|

|

|

14.0 |

|

|

|

14,439 |

|

|

|

12.9 |

|

|

Marking

Products

|

|

|

1,500 |

|

|

|

1.5 |

|

|

|

9,137 |

|

|

|

6.9 |

|

|

|

9,931 |

|

|

|

8.9 |

|

|

Merchandising

Solutions

|

|

|

(56 |

) |

|

|

- |

|

|

|

4,809 |

|

|

|

3.6 |

|

|

|

5,724 |

|

|

|

5.1 |

|

|

|

|

|

20,661 |

|

|

|

20.5 |

|

|

|

32,563 |

|

|

|

24.5 |

|

|

|

30,094 |

|

|

|

26.9 |

|

|

Total

|

|

$ |

101,011 |

|

|

|

100.0 |

% |

|

$ |

132,952 |

|

|

|

100.0 |

% |

|

$ |

111,824 |

|

|

|

100.0 |

% |

In fiscal

2009, approximately 64% of the Company's sales were made from the United States,

and 32%, 2%, 1% and 1% were made from Europe, Canada, Australia and Asia,

respectively. For further information on Segments see Note 16, “Segment

Information” in Item 8 - “Financial Statements and Supplementary Data” on pages

59 and 60 of this report. Bronze segment products are sold throughout the world

with the segment's principal operations located in the United States, Europe,

Canada, and Australia. Casket segment products are primarily sold in

North America. Cremation segment products and services are sold primarily in

North America, Europe, Asia, and Australia. Products and services of

the Graphics Imaging segment are sold primarily in Europe, the United States and

Asia. The Marking Products segment sells equipment and consumables

directly to industrial consumers and distributors in the United States and

internationally through the Company's subsidiaries in Canada, Sweden and China,

and through other foreign distributors. Matthews owns a minority

interest in Marking Products distributors in Asia, Australia and

Europe. Merchandising Solutions segment products and services are

sold principally in the United States.

|

ITEM

1.

|

BUSINESS,

continued

|

MEMORIALIZATION

PRODUCTS AND MARKETS:

Bronze:

The

Bronze segment manufactures and markets products used primarily in the cemetery

and funeral home industries. The segment's products, which are sold

principally in the United States, Europe, Canada and Australia, include cast

bronze memorials and other memorialization products used primarily in

cemeteries. The segment also manufactures and markets cast and etched

architectural products that are produced from bronze, aluminum and other metals,

which are used to identify or commemorate people, places, events and

accomplishments.

Memorial

products, which comprise the majority of the Bronze segment's sales, include

flush bronze memorials, flower vases, crypt plates and letters, cremation urns,

niche units, cemetery features and statues, along with other related products

and services. Flush bronze memorials are bronze plaques which contain personal

information about a deceased individual such as name, birth date, death date and

emblems. These memorials are used in cemeteries as an alternative to

upright and flush granite monuments. The memorials are even or

"flush" with the ground and therefore are preferred by many cemeteries for

easier mowing and general maintenance. In order to provide products

for the granite memorial and mausoleum markets, the Company's other memorial

products include community and family mausoleums, granite monuments and benches,

bronze plaques, letters, emblems, vases, lights and photoceramics that can be

affixed to granite monuments, mausoleums, crypts and flush memorials. Matthews

is a leading builder of mausoleums within North America. Principal

customers for memorial products are cemeteries and memorial parks, which in turn

sell the Company's products to the consumer.

Customers

of the Bronze segment can also purchase memorials and vases on a “pre-need”

basis. The “pre-need” concept permits families to arrange for these

purchases in advance of their actual need. Upon request, the Company

will manufacture the memorial to the customer’s specifications (e.g., name and

birth date) and place it in storage for future delivery. All

memorials in storage have been paid in full with title conveyed to each pre-need

purchaser.

The

Bronze segment manufactures a full line of memorial products for cremation,

including urns in a variety of sizes, styles and shapes. The segment

also manufactures bronze and granite niche units, which are comprised of

numerous compartments used to display cremation urns in mausoleums and

churches. In addition, the Company also markets turnkey cremation

gardens, which include the design and all related products for a cremation

memorial garden.

Architectural

products include cast bronze and aluminum plaques, etchings and letters that are

used to recognize, commemorate and identify people, places, events and

accomplishments. The Company's plaques are frequently used to

identify the name of a building or the names of companies or individuals located

within a building. Such products are also used to commemorate events

or accomplishments, such as military service or financial

donations. The principal markets for the segment's architectural

products are corporations, fraternal organizations, contractors, churches,

hospitals, schools and government agencies. These products are sold

to and distributed through a network of independent dealers including sign

suppliers, awards and recognition companies, and trophy dealers.

Raw

materials used by the Bronze segment consist principally of bronze and aluminum

ingot, sheet metal, coating materials, photopolymers and construction materials

and are generally available in adequate supply. Ingot is obtained

from various North American, European and Australian smelters.

Competition

from other bronze memorialization product manufacturers is on the basis of

reputation, product quality, delivery, price and design availability. The

Company also competes with upright granite monument and flush granite memorial

providers. The Company believes that its superior quality, broad product lines,

innovative designs, delivery capability, customer responsiveness, experienced

personnel and consumer-oriented merchandising systems are competitive advantages

in its markets. Competition in the mausoleum construction industry

includes various construction companies throughout North America and is on the

basis of design, quality and price. Competitors in the architectural

market are numerous and include companies that manufacture cast and painted

signs, plastic materials, sand-blasted wood and other fabricated

products.

ITEM

1. BUSINESS,

continued

Casket:

The

Casket segment is a leading manufacturer and distributor of caskets in North

America. The segment produces two types of caskets: metal and

wood. Caskets can be customized with many different options such as

color, interior design, handles and trim in order to accommodate specific

religious, ethnic or other personal preferences.

Metal

caskets are made from various gauges of cold-rolled steel,

stainless steel, copper and bronze. Metal caskets are generally

categorized by whether the casket is non-gasketed or gasketed, and by material

(i.e., bronze, copper, or steel) and in the case of steel, by the gauge

(thickness) of the metal.

The

segment's wood caskets are manufactured from nine different species of wood, as

well as from veneer. The species of wood used are poplar, pine, ash,

oak, pecan, maple, cherry, walnut and mahogany. The Casket segment is

a leading manufacturer of all-wood constructed caskets, which are manufactured

using pegged and dowelled construction, and include no metal

parts. All-wood constructed caskets are preferred by certain

religious groups.

The

segment also produces casket components. Casket components include

stamped metal parts, metal locking mechanisms for gasketed metal caskets,

adjustable beds, interior panels and plastic ornamental hardware for the

exterior of the casket. Metal casket parts are produced by stamping

cold-rolled

steel, stainless steel, copper and bronze sheets into casket body

parts. Locking mechanisms and adjustable beds are produced by

stamping and assembling a variety of steel parts. Certain ornamental

hardware styles are produced from injection molded plastic. The

segment purchases from sawmills and lumber distributors various species of

uncured wood, which it dries and cures. The cured wood is processed

into casket components.

Additionally,

the segment provides assortment planning and merchandising and display products

to funeral service businesses. These products assist funeral service

professionals in providing value and satisfaction to their client

families.

The

primary materials required for casket manufacturing are cold-rolled

steel and lumber. The segment also purchases copper, bronze, stainless steel,

cloth, ornamental hardware and coating materials. Purchase orders or supply

agreements are typically negotiated with large, integrated steel producers that

have demonstrated timely delivery, high quality material and competitive

prices. Lumber is purchased from a number of sawmills and lumber

distributors. The Company purchases most of its lumber from sawmills

within 150 miles of its wood casket manufacturing facility in York,

Pennsylvania.

The

segment markets its casket products in the United States through a combination

of Company-owned and independent casket distribution facilities. The

Company operates approximately 45 distribution centers in the United

States. Over 75% of the segment’s casket products are currently sold

through Company-owned distribution centers.

The

casket business is highly competitive. The segment competes with other

manufacturers on the basis of product quality, price, service, design

availability and breadth of product line. The segment provides a line

of casket products that it believes is as comprehensive as any of its major

competitors. There are a large number of casket industry participants

operating in North America, and the industry has recently seen a few new foreign

casket manufacturers, primarily from China, enter the North American market. The

Casket segment and its two largest competitors account for a substantial portion

of the finished caskets produced and sold in North America.

Historically,

the segment's operations have experienced seasonal variations. Generally, casket

sales are higher in the second quarter and lower in the fourth quarter of each

fiscal year. These fluctuations are due in part to the seasonal variance in the

death rate, with a greater number of deaths generally occurring in cold weather

months.

|

ITEM

1.

|

BUSINESS,

continued

|

Cremation:

The

Cremation segment has four major groups of products and services: cremation

equipment, cremation caskets, equipment service and repair, and supplies and

urns.

The

Cremation segment is the leading designer and manufacturer of cremation

equipment, serving North America, Europe, Australia and Asia. Cremation

equipment includes systems for cremation of humans and animals, as well as

equipment for processing the cremated remains and other related equipment such

as handling equipment (tables, cooler racks, vacuums). Cremation

equipment and products are sold primarily to funeral homes, cemeteries,

crematories, animal disposers and veterinarians within North America, Europe,

Australia and Asia.

Cremation

casket products consist primarily of three types of caskets: cloth-covered wood,

cloth-covered corrugated material and paper veneer-covered particleboard and

corrugated material. These products are generally used in cremation

and are marketed principally in the United States through independent

distributors and company-owned distribution centers operated by the Company’s

Casket segment.

Service

and repair consists of maintenance work performed on various makes and models of

cremation equipment. This work can be as simple as routine

maintenance offered at-need or through annual service contracts, or as complex

as complete on-site reconstruction. The principal markets for these

services are the owners and operators of cremation equipment. These

services are marketed principally in North America through Company sales

representatives.

Supplies

and urns are consumable items associated with cremation

operations. Supplies distributed by the segment include operator

safety equipment, identification discs and combustible roller

tubes. Urns distributed by the segment include products ranging from

plastic containers to bronze urns for cremated remains. These

products are marketed primarily in North America.

Raw

materials used by the Cremation segment consist principally of structural steel,

sheet metal, electrical components, cloth, wood, particleboard, corrugated

materials, paper veneer and masonry materials and are generally available in

adequate supply from numerous suppliers.

The

Company competes with several manufacturers in the cremation equipment market

principally on the basis of product quality and price. The Cremation

segment and its three largest competitors account for a substantial portion of

the U.S. cremation equipment market. The cremation casket business is

highly competitive. The segment competes with other cremation casket

manufacturers on the basis of product quality, price and design

availability. Although there are a large number of casket industry

participants, the Cremation segment and its two largest competitors account for

a substantial portion of the cremation caskets sold in the United

States.

Historically,

the segment’s cremation casket operations have experienced seasonal

variations. These fluctuations are due in part to the seasonal

variance in the death rate, with a greater number of deaths generally occurring

in cold weather months.

|

ITEM

1.

|

BUSINESS,

continued

|

BRAND SOLUTIONS PRODUCTS AND

MARKETS:

Graphics

Imaging:

The

Graphics Imaging segment provides brand management, pre-press services, printing

plates and cylinders, embossing tools, and creative design services principally

to the primary packaging and corrugated industries. The primary packaging

industry consists of manufacturers of printed packaging materials such as boxes,

flexible packaging, folding cartons and bags commonly seen at retailers of

consumer goods. The corrugated packaging industry consists of manufacturers of

printed corrugated containers. Other major industries served include

the wallpaper, flooring, automotive, and textile industries.

The

principal products and services of this segment include brand management,

pre-press graphics services, printing plates, gravure cylinders, steel bases,

embossing tools, special purpose machinery, engineering assistance, print

process assistance, print production management, digital asset management,

content management, and package design. These products and services

are used by brand owners and packaging manufacturers to develop and print

packaging graphics that identify and help sell the product in the

marketplace. Other packaging graphics can include nutritional

information, directions for product use, consumer warning statements and UPC

codes. The primary packaging manufacturer produces printed packaging from paper,

film, foil and other composite materials used to display, protect and market the

product. The corrugated packaging manufacturer produces printed containers from

corrugated sheets. Using the Company's products, these sheets are

printed and die cut to make finished containers.

The

segment offers a wide array of value-added services and

products. These include print process and print production management

services; print engineering consultation; pre-press preparation, which includes

computer-generated art, film and proofs; plate mounting accessories and various

press aids; and rotary and flat cutting dies used to cut out intricately

designed containers and point-of-purchase displays. The segment also

provides creative digital graphics services to brand owners and packaging

markets.

The

Company works closely with manufacturers to provide the proper printing forms

and tooling used to print the packaging to the user's

specifications. The segment's printing plate products are made

principally from photopolymer resin and sheet materials. Upon

customer request, plates can be pre-mounted press-ready in a variety of

configurations that maximize print quality and minimize press

set-up time. Gravure cylinders, manufactured from steel, copper

and chrome, can be custom engineered for multiple print processes.

The

Graphics Imaging segment customer base consists primarily of brand owners and

packaging industry converters. Brand owners are generally large,

well-known consumer products companies and retailers with a national or global

presence. These types of companies tend to purchase their graphics

needs directly and supply the printing forms, or the electronic files to make

the printing plates and gravure cylinders, to the packaging printer for their

products. The Graphics Imaging segment serves customers primarily in

Europe, the United States and Asia. In Europe, the segment has its

principal operations in Germany, the United Kingdom, Poland and

Austria.

Major raw

materials for this segment's products include photopolymers, copper, steel, film

and graphic art supplies. All such materials are presently available

in adequate supply from various industry sources.

The

Graphics Imaging segment is one of several manufacturers of printing plates and

cylinders and providers of pre-press services with an international

presence. The segment competes in a fragmented industry consisting of

a few multi-plant regional printing form suppliers and a large number of local

single-facility companies located across Europe and the United

States. The combination of the Company's Graphics Imaging business in

Europe, the United States and Asia is an important part of Matthews’ strategy to

become a worldwide leader in the graphics industry and service multinational

customers on a global basis. Competition is on the basis of product

quality, timeliness of delivery, price and value-added services. The

Company differentiates itself from the competition by consistently meeting

customer demands, its ability to service customers nationally and globally, and

its ability to provide value-added services.

|

ITEM

1.

|

BUSINESS,

continued

|

Marking Products:

The

Marking Products segment designs, manufactures and distributes a wide range of

marking and coding products and related consumables, as well as industrial

automation products. The Company’s products are used by manufacturers

and suppliers to identify, track and convey their products and

packaging. Marking products can range from a simple hand stamp to

microprocessor-based ink-jet printing systems. Coding systems often

integrate into the customer’s manufacturing, inventory tracking and conveyance

control systems. The Company manufactures and markets products and

systems that employ the following marking methods to meet customer

needs: contact printing, indenting, etching and ink-jet

printing. Customers will often use a combination of these methods in

order to achieve an appropriate mark. These methods apply product

information required for identification and traceability as well as to

facilitate inventory and quality control, regulatory compliance and brand name

communication.

The

segment’s industrial automation products are based upon embedded control

architecture to create innovative custom solutions which can be

“productized.” Industries that products are created for include oil

exploration, material handling and security scanning. The material

handling industry customers include the largest automated assembly and mail

sorting companies in the United States.

A

significant portion of the revenue of the Marking Products segment is

attributable to the sale of consumables and replacement parts in connection with

the marking, coding and tracking hardware sold by the Company. The

Company develops inks, rubber and steel consumables in harmony with the marking

equipment in which they are used, which is critical to assure ongoing equipment

reliability and mark quality. Many marking equipment customers also

use the Company's inks, solvents and cleaners.

The

principal customers for the Company's marking products are consumer goods

manufacturers, including food and beverage processors, producers of

pharmaceuticals, and manufacturers of durable goods and building

products. The Company also serves a wide variety of industrial

markets, including metal fabricators, manufacturers of woven and non-woven

fabrics, plastic, rubber and automotive products.

A portion

of the segment's sales are outside the United States and are distributed through

the Company's subsidiaries in Canada, Sweden and China in addition to other

international distributors. Matthews owns a minority interest in

distributors in Asia, Australia and Europe.

The

marking products industry is diverse, with companies either offering limited

product lines for well-defined specialty markets, or similar to the Company,

offering a broad product line and competing in various product markets and

countries. In the United States, the Company has manufactured and

sold marking products and related consumable items since 1850.

Major raw

materials for this segment's products include precision components, electronics,

printing components, tool steels, rubber and chemicals, all of which are

presently available in adequate supply from various sources.

Competition

for marking products is based on product performance, integration into the

manufacturing process, service and price. The Company normally

competes with specialty companies in specific brand marking solutions and

traceability applications. The Company believes that, in general, it

offers the broadest line of marking products to address a wide variety of

marking applications.

|

ITEM

1.

|

BUSINESS,

continued

|

Merchandising

Solutions:

The

Merchandising Solutions segment provides merchandising and printing solutions

for manufacturers and retailers. The segment designs, manufactures

and installs merchandising and display systems, and also provides creative

merchandising and marketing solutions services.

The

majority of the segment’s sales are derived from the design, engineering,

manufacturing and installation of merchandising and display

systems. These systems include permanent and temporary displays,

custom store fixtures, brand concept shops, interactive kiosks, custom

packaging, and screen and digitally printed promotional

signage. Design and engineering services include concept and model

development, graphics design and prototyping. Merchandising and

display systems are manufactured to specifications developed by the segment in

conjunction with the customer. These products are marketed and sold

primarily in the United States.

The

segment operates in a fragmented industry consisting primarily of a number of

small, locally operated companies. Industry competition is intense

and the segment competes on the basis of reliability, creativity and providing a

broad array of merchandising products and services. The segment is

unique in its ability to provide in-depth marketing and merchandising services

as well as design, engineering and manufacturing capabilities. These

capabilities allow the segment to deliver complete turnkey merchandising

solutions quickly and cost effectively.

Major raw

materials for the segment’s products include wood, particleboard, corrugated

materials, structural steel, plastic, laminates, inks, film and graphic art

supplies. All of these raw materials are presently available in

adequate supply from various sources.

PATENTS,

TRADEMARKS AND LICENSES:

The

Company holds a number of domestic and foreign patents and

trademarks. However, the Company believes the loss of any or a

significant number of patents or trademarks would not have a material impact on

consolidated operations or revenues.

BACKLOG:

Because

the nature of the Company's Bronze, Graphics Imaging and Merchandising Solutions

businesses are primarily custom products made to order with short lead times,

backlogs are not generally material except for mausoleums. Backlogs vary in a

range of approximately one year of sales for mausoleums. Backlogs for the Casket

segment and the cremation casket businesses are not material. Cremation

equipment sales backlogs vary in a range of eight to ten months of

sales. Backlogs generally vary in a range of up to four weeks of

sales in the Marking Products segment. The Company’s backlog is

expected to be substantially filled in fiscal 2010.

REGULATORY

MATTERS:

The

Company's operations are subject to various federal, state and local laws and

regulations relating to the protection of the environment. These laws

and regulations impose limitations on the discharge of materials into the

environment and require the Company to obtain and operate in compliance with

conditions of permits and other government authorizations. As such,

the Company has developed environmental, health and safety policies and

procedures that include the proper handling, storage and disposal of hazardous

materials.

The

Company is party to various environmental matters. These include

obligations to investigate and mitigate the effects on the environment of the

disposal of certain materials at various operating and non-operating

sites. The Company is currently performing environmental assessments

and remediation at these sites, as appropriate. In addition, prior to

its acquisition, The York Group, Inc. was identified, along with others, by the

Environmental Protection Agency as a potentially responsible party for

remediation of a landfill

site in York, Pennsylvania. At this time, the Company has not been

joined in any lawsuit or administrative order related to the site or its

clean-up.

|

ITEM

1.

|

BUSINESS,

continued

|

At

September 30, 2009, an accrual of approximately $7.3 million had been recorded

for environmental remediation (of which $836,000 was classified in other current

liabilities), representing management's best estimate of the probable and

reasonably estimable costs of the Company's known remediation

obligations. The accrual does not consider the effects of inflation

and anticipated expenditures are not discounted to their present

value. While final resolution of these contingencies could result in

costs different than current accruals, management believes the ultimate outcome

will not have a significant effect on the Company's consolidated results of

operations or financial position.

ITEM

1A. RISK FACTORS.

There are

inherent risks and uncertainties associated with the Company’s businesses that

could adversely affect its operating performance and financial

condition. Set forth below are descriptions of those risks and

uncertainties that the Company currently believes to be

material. Additional risks not currently known or deemed immaterial

may also result in adverse effects on the Company.

Changes in Economic

Conditions. Generally, changes in domestic and international

economic conditions affect the industries in which the Company and its customers

and suppliers operate. These changes include changes in the rate of

consumption or use of the Company’s products due to economic downturns,

volatility in currency exchange rates, and changes in raw material prices

resulting from supply and/or demand conditions.

Uncertainty

about the current unprecedented global economic conditions poses a risk, as

consumers and businesses may continue to postpone or cancel

spending. Other factors that could influence customer spending

include energy costs, conditions in the credit markets, consumer confidence and

other factors affecting consumer spending behavior. These and other

economic factors could have an effect on demand for the Company’s products and

services and negatively impact the Company’s financial condition and results of

operations.

Changes in Foreign Currency Exchange

Rates. Manufacturing

and sales of a significant portion of the Company’s products are outside the

United States, and accordingly, the Company holds assets, incurs liabilities,

earns revenue and pays expenses in a variety of currencies. The

Company’s consolidated financial statements are presented in U.S. dollars, and

therefore, the Company must translate the reported values of its foreign assets,

liabilities, revenue and expenses into U.S. dollars. Increases or

decreases in the value of the U.S. dollar compared to foreign currencies may

negatively affect the value of these items in the Company’s consolidated

financial statements, even though their value has not changed in local

currency.

Increased Prices for Raw

Materials. The Company’s

profitability is affected by the prices of the raw materials used in the

manufacture of its products. These prices may fluctuate based on a

number of factors, including changes in supply and demand, domestic and global

economic conditions, currency exchange rates, labor costs and fuel-related costs. If

suppliers increase the price of critical raw materials, alternative sources of

supply, or an alternative material, may not exist. In addition, to

the extent that the Company has quoted prices to or has existing contracts with

customers, it may be unable to increase the price of its products to offset the

increased costs. Significant raw material price increases that cannot

be mitigated by selling price increases or productivity improvements will

negatively affect the Company’s results of operations.

ITEM

1. BUSINESS,

continued

Changes in Mortality and Cremation

Rates. Generally,

life expectancy in the United States and other countries in which the Company’s

Memorialization businesses operate has increased steadily for several decades

and is expected to continue to do so in the future. The increase in

life expectancy is also expected to impact the number of deaths in the

future. Additionally, cremations have steadily grown as a percentage

of total deaths in the United States since the 1960’s, and are expected to

continue to increase in the future. The Company expects that these

trends will continue in the future, and the result may affect the volume of

bronze memorialization products and burial caskets sold in the United

States. However, sales of the Company’s Cremation segment may benefit

from the growth in cremations.

Changes in Product Demand or Pricing.

The Company’s businesses have and will continue to operate in competitive

markets. Changes in product demand or pricing are affected by domestic and

foreign competition and an increase in consolidated purchasing by large

customers operating in both domestic and global markets. The Memorialization

businesses generally operate in markets with ample supply capacity and demand

which is correlated to death rates. The Brand Solutions businesses

serve global customers that are requiring their suppliers to be global in scope

and price competitive. Additionally, in recent years the Company has

witnessed an increase in products manufactured offshore, primarily in China, and

imported into the Company’s U.S. markets. It is expected that these

trends will continue and may affect the Company’s future results of

operations.

Risks in Connection with

Acquisitions. The Company

has grown in part through acquisitions, and continues to evaluate acquisition

opportunities that have the potential to support and strengthen its

businesses. There is no assurance however that future acquisition

opportunities will arise, or that if they do, that they will be

consummated. In addition, acquisitions involve inherent risks that

the businesses acquired will not perform in accordance with expectations, or

that synergies expected from the integration of the acquisitions will not be

achieved as rapidly as expected, if at all. Failure to effectively integrate

acquired businesses could prevent the realization of expected rates of return on

the acquisition investment and could have a negative effect on the Company’s

results of operations and financial condition.

Technological Factors Beyond the

Company’s Control. The Company

operates in certain markets in which technological product development

contributes to its ability to compete effectively. There can be no

assurance that the Company will be able to develop new products, that new

products can be manufactured and marketed profitably, or that new products will

successfully meet the expectations of customers.

Changes in the Distribution of the

Company’s Products or the Loss of a Large Customer. Although the

Company does not have any customer that is considered individually significant

to consolidated sales, it does have contracts with several large customers in

both the Memorialization and Brand Solutions businesses. While these

contracts provide important access to large purchasers of the Company’s

products, they can obligate the Company to sell products at contracted prices

for extended periods of time which may, in the short-term, limit the Company’s

ability to increase prices in response to significant raw material price

increases or other factors. Additionally, any significant divestiture

of business properties or operations by current customers could result in a loss

of business if the Company is not able to maintain the business with the

subsequent owners of the properties.

ITEM

1B. UNRESOLVED STAFF COMMENTS.

Not

Applicable.

Principal

properties of the Company and its majority-owned subsidiaries as of October 31,

2009 were as follows (properties are owned by the Company except as

noted):

|

Location

|

|

Description

of Property

|

|

|

Bronze:

|

|

|

|

|

Pittsburgh,

PA

|

|

Manufacturing

/ Division Offices

|

|

|

Kingwood,

WV

|

|

Manufacturing

|

|

|

Melbourne,

Australia

|

|

Manufacturing

|

(1)

|

|

Parma,

Italy

|

|

Manufacturing

/ Warehouse

|

(1)

|

|

Searcy,

AR

|

|

Manufacturing

|

|

|

Seneca

Falls, NY

|

|

Manufacturing

|

|

|

|

|

|

|

|

Casket

(2):

|

|

|

|

|

Monterrey,

Mexico

|

|

Manufacturing

|

(1)

|

|

Richmond,

IN

|

|

Manufacturing

|

(1)

|

|

Richmond,

IN

|

|

Manufacturing

/ Metal Stamping

|

|

|

Richmond,

IN

|

|

Injection

Molding

|

(1)

|

|

York,

PA

|

|

Manufacturing

|

|

|

|

|

|

|

|

Cremation:

|

|

|

|

|

Apopka,

FL

|

|

Manufacturing

/ Division Offices

|

|

|

Richmond,

IN

|

|

Manufacturing

|

(1)

|

|

Udine,

Italy

|

|

Manufacturing

|

(1)

|

|

|

|

|

|

|

Graphics

Imaging:

|

|

|

|

|

Pittsburgh,

PA

|

|

Manufacturing

/ Division Offices

|

|

|

Julich,

Germany

|

|

Manufacturing

/ Division Offices

|

|

|

Atlanta,

GA

|

|

Manufacturing

|

|

|

Beverly,

MA

|

|

Manufacturing

|

(1)

|

|

Bristol,

England

|

|

Manufacturing

|

|

|

Dallas,

TX

|

|

Manufacturing

|

(1)

|

|

Goslar,

Germany

|

|

Manufacturing

|

(1)

|

|

Leeds,

England

|

|

Manufacturing

|

(1)

|

|

Monchengladbach,

Germany

|

|

Manufacturing

|

|

|

Munich,

Germany

|

|

Manufacturing

|

(1)

|

|

Nuremberg,

Germany

|

|

Manufacturing

|

(1)

|

|

Oakland,

CA

|

|

Manufacturing

|

(1)

|

|

Poznan,

Poland

|

|

Manufacturing

|

|

|

St.

Louis, MO

|

|

Manufacturing

|

|

|

Shenzhen,

China

|

|

Manufacturing

|

(1)

|

|

Vienna,

Austria

|

|

Manufacturing

|

(1)

|

|

Vreden,

Germany

|

|

Manufacturing

|

|

|

Wan

Chai, Hong Kong

|

|

Manufacturing

|

(1)

|

|

|

|

|

|

|

Marking

Products:

|

|

|

|

|

Pittsburgh,

PA

|

|

Manufacturing

/ Division Offices

|

|

|

Gothenburg,

Sweden

|

|

Manufacturing

/ Distribution

|

(1)

|

|

Tualatin,

OR

|

|

Manufacturing

|

(1)

|

|

Beijing,

China

|

|

Manufacturing

|

(1)

|

|

|

|

|

|

|

ITEM

2.

|

PROPERTIES,

continued

|

|

Location

|

|

Description

of Property

|

|

|

|

|

|

|

|

Merchandising

Solutions:

|

|

|

|

|

East

Butler, PA

|

|

Manufacturing

/ Division Offices

|

|

|

|

|

|

|

|

Corporate

Office:

|

|

|

|

|

Pittsburgh,

PA

|

|

General

Offices

|

|

|

(1)

|

These

properties are leased by the Company under operating lease arrangements.

Rent expense incurred by the Company for all leased facilities was

approximately $13.3 million in fiscal

2009.

|

|

(2)

|

In

addition to the properties listed, the Casket division leases warehouse

facilities totaling approximately 836,000 square feet in 23 states under

operating leases.

|

All of

the owned properties are unencumbered. The Company believes its

facilities are generally well suited for their respective uses and are of

adequate size and design to provide the operating efficiencies necessary for the

Company to be competitive. The Company's facilities provide adequate

space for meeting its near-term production requirements and have availability

for additional capacity. The Company intends to continue to expand

and modernize its facilities as necessary to meet the demand for its

products.

|

|

ITEM

3. LEGAL PROCEEDINGS.

|

Matthews

is subject to various legal proceedings and claims arising in the ordinary

course of business. Management does not expect that the results of

any of these legal proceedings will have a material adverse effect on Matthews’

financial condition, results of operations or cash flows.

ITEM

4. SUBMISSION OF MATTERS TO A VOTE OF SECURITY HOLDERS.

No

matters were submitted to a vote of the Company's security holders during the

fourth quarter of fiscal 2009.

OFFICERS

AND EXECUTIVE MANAGEMENT OF THE REGISTRANT

The

following information is furnished with respect to officers and executive

management as of October 31, 2009:

|

Name

|

|

Age

|

|

Positions

with Registrant

|

|

|

|

|

|

|

|

Joseph

C. Bartolacci

|

|

49

|

|

President

and Chief Executive Officer

|

|

|

|

|

|

|

|

David

F. Beck

|

|

57

|

|

Controller

|

|

|

|

|

|

|

|

Jennifer

A. Ciccone

|

|

42

|

|

Vice

President, Human Resources

|

|

|

|

|

|

|

|

C.

Michael Dempe

|

|

53

|

|

Chief

Operating Officer, IDL Worldwide, Inc.

|

|

|

|

|

|

|

|

James

P. Doyle

|

|

58

|

|

Group

President, Memorialization

|

|

|

|

|

|

|

|

Brian

J. Dunn

|

|

52

|

|

Group

President, Graphics and Marking Products

|

|

|

|

|

|

|

|

Paul

C. Jensen

|

|

51

|

|

President,

Marking Products Division

|

|

|

|

|

|

|

|

Sean

F. Lydon

|

|

46

|

|

President,

Packaging Graphics Division

|

|

|

|

|

|

|

|

Steven

F. Nicola

|

|

49

|

|

Chief

Financial Officer, Secretary and Treasurer

|

|

|

|

|

|

|

|

Paul

F. Rahill

|

|

52

|

|

President,

Cremation Division

|

|

|

|

|

|

|

|

Franz

J. Schwarz

|

|

61

|

|

President,

Graphics Europe

|

|

|

|

|

|

|

|

Brian

D. Walters

|

|

40

|

|

Vice

President and General Counsel

|

|

|

|

|

|

|

Joseph C. Bartolacci was

appointed President and Chief Executive Officer effective October 1,

2006. He had been President and Chief Operating Officer since

September 1, 2005. Mr. Bartolacci was elected to the Board of

Directors on November 15, 2005. He had been President, Casket

Division since February 2004 and Executive Vice President of Matthews since

January 1, 2004. He had been President, Matthews Europe since April

2002. Prior thereto, he was President, Caggiati, S.p.A. (a wholly-owned

subsidiary of Matthews International Corporation) and served as General Counsel

of Matthews.

David F. Beck was appointed

Controller effective September 15, 2003.

Jennifer A. Ciccone was

appointed Vice President, Human Resources effective February 19,

2009. Prior thereto, Ms. Ciccone had been Director, Corporate Human

Resources since 2006. Ms. Ciccone joined the Company in 1998 and has

held various managerial positions within the Company’s Human Resources

Department.

C. Michael Dempe has served as

Chief Operating Officer of IDL Worldwide, Inc. (formerly Cloverleaf Group,

Inc.), a wholly-owned subsidiary of Matthews, since July 2004.

James P. Doyle joined the

Company as Group President, Memorialization in December 2006. Prior

to joining Matthews, he served as President, Kohler Engine Business (a

manufacturer of air and liquid-cooled four cycle engines), a division of Kohler

Company, from 2004 to 2006.

Brian J. Dunn was appointed

Group President, Graphics and Marking Products effective September 1,

2007. Prior thereto, Mr. Dunn had been President, Marking Products

Division.

OFFICERS AND EXECUTIVE

MANAGEMENT OF THE REGISTRANT, continued

Paul C. Jensen was appointed

President, Marking Products Division in November 2008. Prior thereto,

Mr. Jensen served as Vice President, Division Technology for the Marking

Products Division from March 2007, and served as Vice President of Holjeron

Corporation, a wholly-owned subsidiary of Matthews, since July

2004.

Sean F. Lydon was appointed

President, Packaging Graphics Division in October 2008. He joined

Matthews in July 2008 as an Operations Manager in the Company’s Graphics Imaging

segment. Prior to joining Matthews, he served as Director, Supply

Chain Operations at Sony Electronics from 2001 to 2008.

Steven F. Nicola was appointed

Chief Financial Officer, Secretary and Treasurer effective December 1,

2003.

Paul F. Rahill was appointed

President, Cremation Division in October 2002.

Franz J. Schwarz was named

President, Graphics Europe in May 2006. He had been Managing Director

of S+T Reprotechnik GmbH (“S+T GmbH”) (formerly Matthews International GmbH), a

wholly-owned subsidiary of Matthews International Corporation, since 2000. He

was a partial owner of S+T GmbH, a provider of printing plates and print

services located in Julich, Germany, until September 30,

2005. Matthews owns 100% of S+T GmbH.

Brian D. Walters was appointed

Vice President and General Counsel effective February 19, 2009. Mr.

Walters joined the Company as Legal Counsel in 2005. Prior to joining

the Company, Mr. Walters was a partner with Fried, Walters, Zuschlag &

Grochmal, a law firm in Pittsburgh, Pennsylvania.

PART

II

|

|

ITEM

5. MARKET FOR REGISTRANT'S COMMON EQUITY AND RELATED

STOCKHOLDER MATTERS.

|

Market

Information:

The

authorized common stock of the Company consists of 70,000,000 shares of Class A

Common Stock, $1 par value. The Company's Class A Common Stock is

traded on the NASDAQ Global Select Market System under the symbol

“MATW”. The following table sets forth the high, low and closing

prices as reported by NASDAQ for the periods indicated:

|

|

|

High

|

|

|

Low

|

|

|

Close

|

|

|

Fiscal

2009:

|

|

|

|

|

|

|

|

|

|

|

Quarter

ended: September 30,

2009

|

|

$ |

36.79 |

|

|

$ |

28.00 |

|

|

$ |

35.38 |

|

|

June

30, 2009

|

|

|

32.17 |

|

|

|

27.11 |

|

|

|

31.12 |

|

|

March

31, 2009

|

|

|

40.52 |

|

|

|

27.67 |

|

|

|

28.81 |

|

|

December

31, 2008

|

|

|

51.05 |

|

|

|

32.30 |

|

|

|

36.68 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Fiscal

2008:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Quarter

ended: September 30,

2008

|

|

$ |

58.55 |

|

|

$ |

43.71 |

|

|

$ |

50.74 |

|

|

June

30, 2008

|

|

|

52.00 |

|

|

|

44.92 |

|

|

|

45.26 |

|

|

March

31, 2008

|

|

|

50.75 |

|

|

|

43.28 |

|

|

|

48.25 |

|

|

December

31, 2007

|

|

|

49.50 |

|

|

|

39.93 |

|

|

|

46.87 |

|

The

Company has a stock repurchase program, which was initiated in

1996. Under the program, the Company's Board of Directors has

authorized the repurchase of a total of 12,500,000 shares of Matthews’ common

stock, of which 12,279,922 shares have been repurchased as of September 30,

2009. The buy-back program is designed to increase shareholder value,

enlarge the Company's holdings of its common stock, and add to earnings per

share. Repurchased shares may be retained in treasury, utilized for

acquisitions, or reissued to employees or other purchasers, subject to the

restrictions of the Company’s Restated Articles of Incorporation.

All

purchases of the Company’s common stock during fiscal 2009 were part of this

repurchase program.

|

ITEM

5.

|

MARKET FOR

REGISTRANT'S COMMON EQUITY AND RELATED STOCKHOLDER MATTERS,

continued

|

The

following table shows the monthly fiscal 2009 stock repurchase

activity:

|

Period

|

|

Total

number of shares purchased

|

|

|

Average

price paid per share

|

|

|

Total

number of shares purchased as part of a publicly announced

plan

|

|

|

Maximum

number of shares that may yet be purchased under the plan

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

October

2008

|

|

|

295,000 |

|

|

$ |

43.14 |

|

|

|

295,000 |

|

|

|

721,994 |

|

|

November

2008

|

|

|

40,266 |

|

|

|

35.45 |

|

|

|

40,266 |

|

|

|

681,728 |

|

|

December

2008

|

|

|

45,000 |

|

|

|

37.64 |

|

|

|

45,000 |

|

|

|

636,728 |

|

|

January

2009

|

|

|

10,000 |

|

|

|

33.66 |

|

|

|

10,000 |

|

|

|

626,728 |

|

|

February

2009

|

|

|

52,500 |

|

|

|

35.43 |

|

|

|

52,500 |

|

|

|

574,228 |

|

|

March

2009

|

|

|

172,500 |

|

|

|

29.49 |

|

|

|

172,500 |

|

|

|

401,728 |

|

|

April

2009

|

|

|

47,500 |

|

|

|

27.96 |

|

|

|

47,500 |

|

|

|

354,228 |

|

|

May

2009

|

|

|

600 |

|

|

|

29.60 |

|

|

|

600 |

|

|

|

353,628 |

|

|

June

2009

|

|

|

93,050 |

|

|

|

30.62 |

|

|

|

93,050 |

|

|

|

260,578 |

|

|

July

2009

|

|

|

- |

|

|

|

- |

|

|

|

- |

|

|

|

260,578 |

|

|

August

2009

|

|

|

500 |

|

|

|

36.03 |

|

|

|

500 |

|

|

|

260,078 |

|

|

September

2009

|

|

|

40,000 |

|

|

|

35.39 |

|

|

|

40,000 |

|

|

|

220,078 |

|

|

Total

|

|

|

796,916 |

|

|

$ |

36.09 |

|

|

|

796,916 |

|

|

|

|

|

Holders:

Based on

records available to the Company, the number of registered holders of the

Company's common stock was 531 at October

31, 2009.

Dividends:

A

quarterly dividend of $.07 per share was paid for the fourth quarter of fiscal

2009 to shareholders of record on November 2, 2009. The Company paid quarterly

dividends of $.065 per share for the first three quarters of fiscal 2009 and the

fourth quarter of fiscal 2008. The Company paid quarterly

dividends of $.06 per share for the first three quarters of fiscal 2008 and the

fourth quarter of fiscal 2007. The Company paid quarterly dividends

of $.055 per share for the first three quarters of fiscal 2007.

Cash

dividends have been paid on common shares in every year for at least the past

forty years. It is the present intention of the Company to continue

to pay quarterly cash dividends on its common stock. However, there

is no assurance that dividends will be declared and paid as the declaration and

payment of dividends is at the discretion of the Board of Directors of the

Company and is dependent upon the Company's financial condition, results of

operations, cash requirements, future prospects and other factors deemed

relevant by the Board.

|

ITEM

5.

|

MARKET FOR

REGISTRANT'S COMMON EQUITY AND RELATED STOCKHOLDER MATTERS,

continued

|

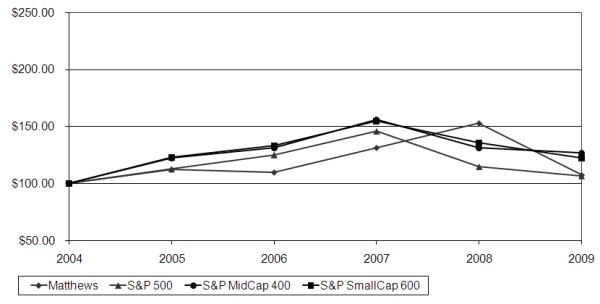

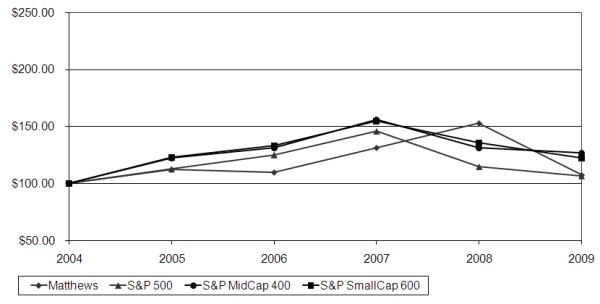

Performance

Graph:

COMPARISON

OF FIVE-YEAR CUMULATIVE RETURN *

AMONG

MATTHEWS INTERNATIONAL CORPORATION,

S&P

500 INDEX, S&P MIDCAP 400 INDEX AND S&P SMALLCAP 600 INDEX

**

* Total

return assumes dividend reinvestment

** Fiscal

year ended September 30

Note:

Performance graph assumes $100 invested on October 1, 2004 in Matthews

International Corporation Common Stock, Standard & Poor's (S&P) 500

Index, S&P MidCap 400 Index and S&P SmallCap 600 Index. The

results are not necessarily indicative of future performance.

|

|

ITEM

6. SELECTED FINANCIAL

DATA.

|

|

|

|

Years

Ended September 30,

|

|

|

|

|

2009(1)

|

|

|

2008(2)

|

|

|

2007(3)

|

|

|

2006(4)

|

|

2005

|

|

|

|

|

(Amounts

in thousands, except per share data)

|

|

|

|

|

(Not Covered by Report of Independent Registered Public Accounting

Firm)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Net

sales

|

|

$ |

780,908 |

|

|

$ |

818,623 |

|

|

$ |

749,352 |

|

|

$ |

715,891 |

|

|

$ |

639,822 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Gross

profit

|

|

|

294,777 |

|

|

|

322,964 |

|

|

|

280,457 |

|

|

|

271,933 |

|

|

|

223,075 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Operating

profit

|

|

|

101,011 |

|

|

|

132,952 |

|

|

|

111,824 |

|

|

|

113,884 |

|

|

|

98,413 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Interest

expense

|

|

|

12,053 |

|

|

|

10,405 |

|

|

|

8,119 |

|

|

|

6,995 |

|

|

|

2,966 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Income

before income taxes

|

|

|

88,543 |

|

|

|

121,572 |

|

|

|

103,716 |

|

|

|

105,408 |

|

|

|

93,056 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Income

taxes

|

|

|

30,811 |

|

|

|

42,088 |

|

|

|

38,990 |

|

|

|

38,964 |

|

|

|

34,985 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Net

income

|

|

$ |

57,732 |

|

|

$ |

79,484 |

|

|

$ |

64,726 |

|

|

$ |

66,444 |

|

|

$ |

58,071 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Earnings

per common share:

|

|

|

|

|